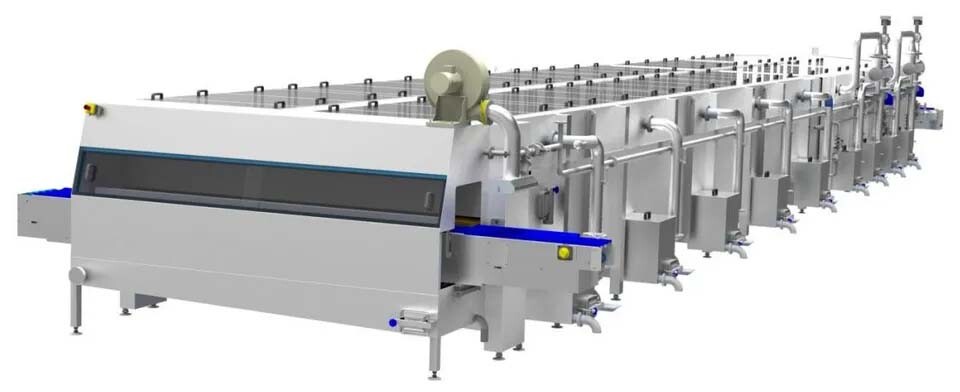

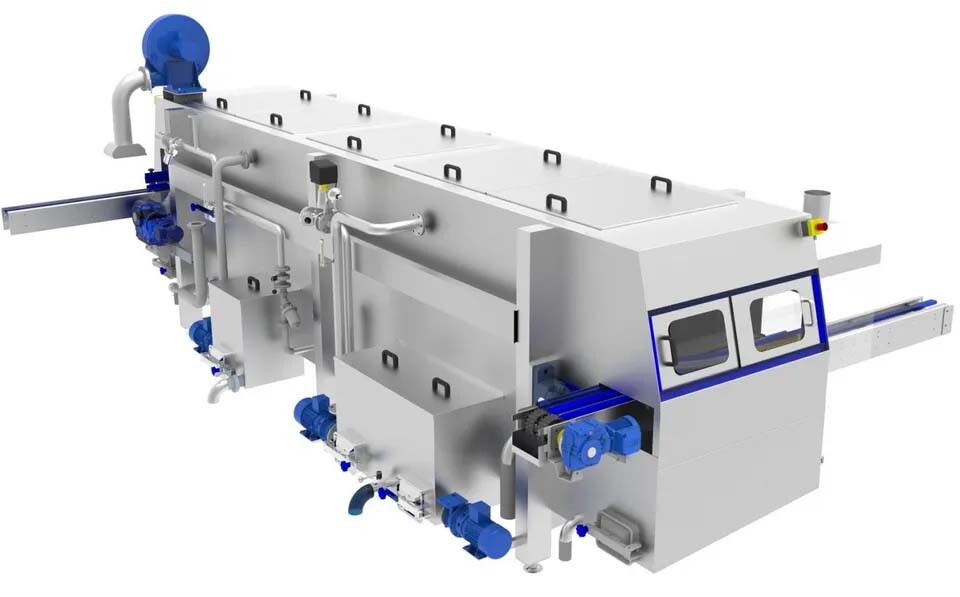

Tunnel-Cooler

Type_091

Operation takes place continuously on conveyor belts of different designs, adapted to the container shapes and dimensions to be processed.

To cool the containers, water (eg well water or ice water) is circulated countercurrently to the product stream and sprayed over the products with pumps and nozzle sticks. For heat recovery and the associated increased energy efficiency, use of intermediate heat exchangers is advantageous. The associated separation of the cooling circuit in the primary and secondary circuit usually leads to longer service life due to reduced dirt entry.

-

Machine design in Cr-Ni steel 1.4301 (AISI 304)

-

Tailor-made sizes, tailored to the performance and circumstances of the customer

-

Version with passive or active holding line for headspace pasteurization possible

You and niko - Let's plan our joint project now.

With niko at your side, you can look forward to successful cooperation and optimal production in the food industry. Our wide range of products, our custom-fit solutions and our first-class support will help you achieve your goals. Contact us now and let's work together on your future.

Contact us now!