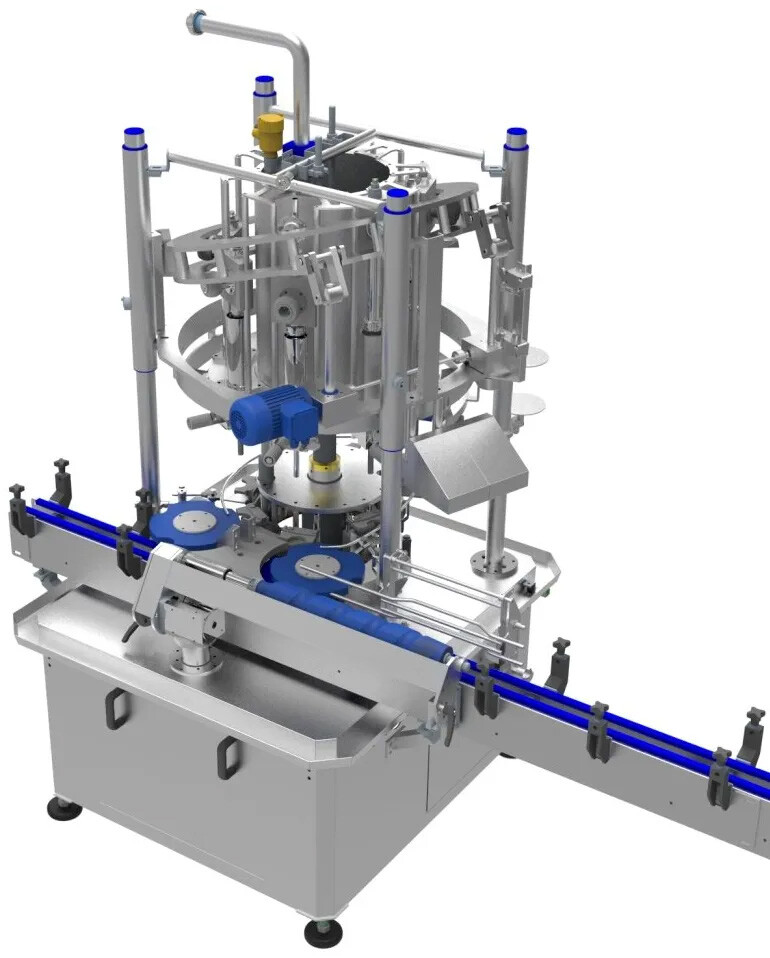

Piston Filler

As a rotary machine, for filling pasty products, with and without solid particles, into cans or jars. Containers are fed to the rotary filler by means of a screw and infeed starwheel and placed below the filling valves. During the rotary cycle, filling valves and filling pistons are cam-controlled so that product in the filling tank is conveyed into the containers. Gentle filling thanks to short product paths, generously dimensioned and flow-optimized intake and filling cross-sections, free of dead space. The filled containers leave the carousel via a discharge starwheel and reach the discharge conveyor.

The machine completely consists of Cr-Ni-steel 1.4301 / 1.4404 (AISI 304/316) or any other stainless material, such as plastics, with the exception of drive and bearing components.

Possible equipment features:

- Control piston without wearing sealing rings, in Waukesha design.

- Intake and filling volume can be adjusted on each cylinder

- Motorized adjustment for container height and filling volume

- Piston easy to dismantle and clean

- Quick and easy changeover to other containers (format change)

- Spring section with safety shut-off switch for incorrectly entering, tipped over containers

- Safety doors with electric tumbler

- Control panel with touch screen and control buttons on the machine

- Servo technology design to reduce guide play / eliminate gear wear

- Drives in clean-design stainless steel design, encapsulated

- Jog control for machine set-up

- Cleaning nozzle rack with solenoid switching valve

- lifting actuator for pulling out of the pistons and automatic rinsing/cleaning

You and niko - Let's plan our joint project now.

With niko at your side, you can look forward to successful cooperation and optimal production in the food industry. Our wide range of products, our custom-fit solutions and our first-class support will help you achieve your goals. Contact us now and let's work together on your future.

Contact us now!