Headspacer

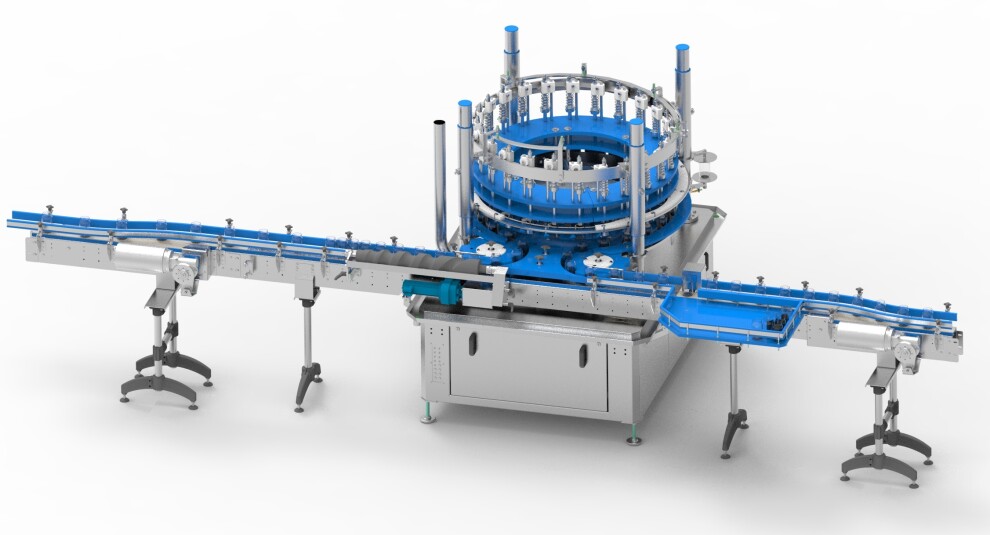

As a rotary running machine, for automatic adjustment of the headspace inside containers and to avoid sealing problems caused by protruding product, such as cucumbers, carrots, beans, slices or sticks. Containers are fed to the carousel by means of a screw and infeed starwheel and placed below the tamping heads. Before it is gently pressed in, the protruding product - sometimes leaning on the edge of the container mouth - can be centered/uprighted. The product is then pressed deeper into the container. As an alternative to product centering, fibrous product can be squeezed off on the edge of the container. If it is not possible to press the product in sufficiently to a certain depth, the respective spring-loaded tamping head disengages upwards and is detected. In this way, glass breakage due to too high stamping force is avoided. The tampered containers leave the carousel via a discharge starwheel and reach the discharge conveyor. The detected mis-tampered containers are discharged from the belt onto a collecting plate or belt.

The machine completely consists of Cr-Ni-steel 1.4301 (AISI 304) or any other stainless material, such as plastics, with the exception of drive and bearing components.

Possible equipment features:

- Gentle pressing of the product so that it can compress evenly or lie in free spaces in the container.

- Product centering for uprighting of product leaning over the edge of the container mouth (e.g. for cucumbers)

- Alternative: Rotating squeezing rings around tamping heads, which spring onto the edge of the container mouth and shear off product residues.

- Container protection against too much tampering force, as well as ejection of mis-tampered containers

- Spring section with safety shut-off switch for incorrectly entering, tipped over packs

- Safety doors with electrical tumbler

- Control panel with touch screen and control buttons on the machine

- Motorized height adjustment

- Servo technology design to reduce guide play / eliminate gear wear

- Drives in clean-design stainless steel design, encapsulated

- Jog control for machine set-up

- Also in combination with a vacuum unit (combi-block)

You and niko - Let's plan our joint project now.

With niko at your side, you can look forward to successful cooperation and optimal production in the food industry. Our wide range of products, our custom-fit solutions and our first-class support will help you achieve your goals. Contact us now and let's work together on your future.

Contact us now!