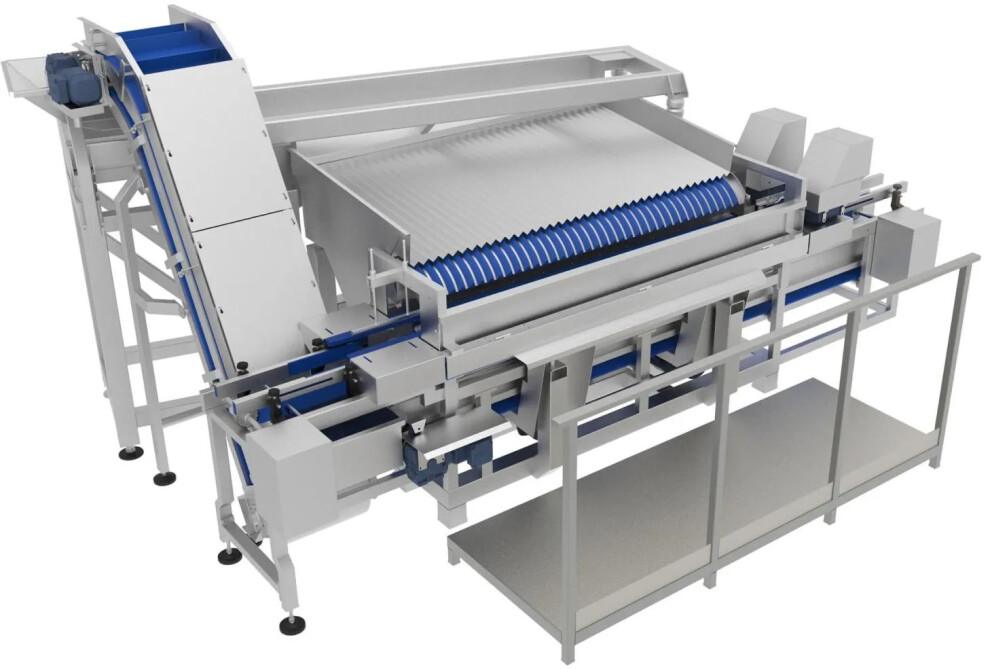

High-Performance Long-Filler (HLF)

As a linear filling machine with vibrating feeder and filling table. For filling almost all chunky products such as cucumbers, onions, beet, cherries, olives, carrots, plums, blueberries, etc. into dimensionally stable containers. Effective filling with gentle handling of the product. The product is picked up in the top-mounted vibratory feeder and discharged evenly over an inclined edge to the filling table (belt or vibratory table) below. The conveyor table drops an evenly distributed layer of product close above the containers so that most of it goes directly into the mouth. The containers are fed through the machine by means of a clamping chain. Product that falls past and through the containers passes onto a belt and is conveyed by this and a return elevator back to the vibratory feeder. The machine is controlled operator-dependently on the panel, the pack flow and the correct filling must be adjusted to the product feed.

Capacity up to 300/min, depending on the container, at 3m filling table width.

Construction in Cr-Ni steel 1.4301/1.4404 (AISI 304/316) or in other non-rusting materials, such as plastic (with the exception of the drive and bearing elements).

- Robust, low-maintenance construction

- Round tube frame design, for simplified cleaning

- Working platform with railing in front of machine

- No format parts to change

- Adjustable clamping chain for containers up to approx. 235mm (10/1 can)

- Vibration at the clamping chain conveyor, for optimized product infeed and distribution in the containers

- Adjustable height of discharge edge of filling table for gentle product let-off directly above containers, heights up to approx. 260mm

- Adjustable baffle wall opposite of the filling table, to better guide products into container mouths

- Filling table as v-shaped vibratory chutes or belt depending on product range

- Filling table as belt optionally with attachable alignment rods for elongated products (e.g. cucumbers)

- Machine available in filling widths of 1, 2 or 3 meters depending on output

- Movable, height-adjustable control panel with touch screen and control buttons on the machine

- Drives in clean-design stainless steel execution, encapsulated

- Emergency rope above the filling table for immediate stop

- Discharge side blow-off of the headspace

- Blow-off nozzle assembly at elevator outlet to remove sticking product rests

- Cleaning nozzles for easier cleaning

- Inching switch for slow run through for cleaning

- Adjustable deflector in vibratory feeder to optionally feed only parts of the filling table

- Elevator belt cover

- Collecting tray below the return belt/elevator for juice/product

You and niko - Let's plan our joint project now.

With niko at your side, you can look forward to successful cooperation and optimal production in the food industry. Our wide range of products, our custom-fit solutions and our first-class support will help you achieve your goals. Contact us now and let's work together on your future.

Contact us now!